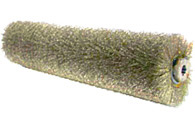

Brass Wire Cylinder Brushes

Brass wire cylinder brushes are softer than comparable brushes filled with steel wire or stainless steel wire, and offer a brushing action that will not scratch harder metals. Our brass wire is Alloy 260, composed of 70% Copper and 30% Zinc. If your work-piece is either brass or copper, then brass wire may be the most suitable choice. Brass wire (as well as bronze wire) will not generate sparks when struck against other metallic surfaces, and may be suitable for hazardous environments(1) . Brass wire is also an excellent conductor of electrical energy (28% IACS), and is suitable for static reduction applications when incorporated into a brass, steel, or stainless steel channel backing. Brass wire is appropriate for operating environments up to 300°F constant temperature. Brass wire cylinder brushes are also relatively corrosion resistant. Spiral Brush offers brass cylinder brushes made from the following sizes of crimped brass wire: Crimped Brass Wire Diameters

| .004″ | .0055″ | .008″ | .010″ | .012″ | .015″ | .020″ |

Cylindrical brass brushes are ideal for wide face brushing or cleaning in production environments, such as conveyor cleaning, or surface roughening for adhesion. Spiral wound brass cylinder brushes are based on our strip brush technology, and are individually designed to meet the customer’s specifications. Paddle wheel style brass conveyor cleaning brushes also utilize our strip brush technology and offer a customer-refillable brush core. Spiral Brush has brass cylinder brush design experience in a broad range of applications including:

Cylindrical brass brushes are ideal for wide face brushing or cleaning in production environments, such as conveyor cleaning, or surface roughening for adhesion. Spiral wound brass cylinder brushes are based on our strip brush technology, and are individually designed to meet the customer’s specifications. Paddle wheel style brass conveyor cleaning brushes also utilize our strip brush technology and offer a customer-refillable brush core. Spiral Brush has brass cylinder brush design experience in a broad range of applications including:

- Conveyor Cleaning

- Scrubbing or Surface roughening applications

- Material handling applications

- Cleaning metal parts without removing any of the base material

- Satin finishing aluminum extrusions or sheet

To learn more about brass cylinder brushes, view our ![]() PDF catalog or contact us.

PDF catalog or contact us.

Brass Cylinder Brush Mounting Options:

- Shaft: We can manufacture a solid or tubular shaft to your drawings or specifications, or you can supply your own shaft. Shafts may include keyways as required for drive purposes. Cylindrical brushes can be welded directly to the shaft or secured by means of metal clips attached to the shaft. Brushes mounted on a shaft are typically refillable as long as the shaft remains in good condition.

- Throw-Away Core: For the convenience of easy replacement, we can assemble the cylinder brush on an economical thin- wall tube with end-bushings to be mounted onto the customer’s driven shaft. Rather than maintaining a spare brush on hand and returning the entire worn brush for refill, simply order a new brush and install it in the place of the old brush.

- Refillable Core: For a more economical long term solution, the core can be made from heavier wall tube and can be returned for refill multiple times. The shaft or journals may be an integral part of the core design or may be removable for ease of replacement. Refilling saves the cost of remaking the shaft or core.

- Unmounted Brush Refill: Customers may choose to buy the loose wound brush coil to mount on their own shaft or cores.

- Dynamic Balancing: For cylinder brushes operating at higher speeds, in excess of 350 to 500 revolutions per minute and also depending on weight and size considerations, dynamic balancing may be recommended to reduce vibration and improve the consistency of brushing action.

- Crating: Due to weight, size, and other shipping considerations, cylinder brushes over a certain size will be considered for packaging in a wooden crate which may be reused for future refill transportation purposes. This determination is made at the time of brush design, and the cost of the crate is quoted separately.

To learn more about cylinder brush mounting options, contact us.

Contact Spiral Brush For Your Cylindrical Brass Brush Needs

Our engineers and experienced customer service associates work with you to understand the application, the material to be brushed, the desired finish, the operating environment, and the equipment on which your brass cylinder brush will be installed. We will help you to determine the appropriate core, shaft, channel size and brush materials, establish power requirements, a recommended range of operating speed, and determine the need for dynamically balancing the cylinder brush. To learn more about cylindrical brass brushes, or to request a quote, contact Spiral Brushes today.

—

(1) NOTE REGARDING HAZARDOUS ENVIRONMENT APPLICATIONS: Other components of a brass wire brush, such as the channel base, holding wire, brush holder, shaft, mounting tube, and bushings, might not provide the same non-sparking performance, so be sure to evaluate the entire brush and its interaction with the application before using the brush in a hazardous environment.