Nylon Strip Brushes

Nylon fill strip brushes offer the following characteristics in most applications: excellent fatigue life, good abrasion resistance, low to moderate absorption of water (3% to 9%) leading to only a temporary reduction in stiffness, an excellent bend recovery rate, resistance to most common solvents, and suitability for use in weak acids.

For a custom quote on nylon strip brushes, start by selecting a channel size from the chart below:

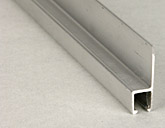

| Strip Brush Diagram | Channel Size |

(A) Base Width ± .010″ |

(B) Leg Height ± .010″ |

Minimum Visible Trim |

Synthetic Fill Size Range |

Send RFQ |

|---|---|---|---|---|---|---|

|

4 | .190″ | .195″ | 0.5″ | .003″-.014″ | |

| 5 | .210” | .250” | 0.625” | .003”-.020” | ||

| 7 | .300” | .315” | 0.75” | .003”-.060” | ||

| 8 | .335” | .375” | 0.75” | .003”-.120” | ||

| 10 | .385” | .480” | 1.0” | .003”-.120” | ||

| 12 | .430” | .565” | 1.0″ | .003”-.120” |

Channel base material options for nylon brush strip lengths include:

- Galvanized Steel – most economical

- Stainless Steel – resists corrosion

- Brass – low electrical resistance

- Aluminum – resists corrosion, lightweight

Nylon strip brushes, feature a formable metal structural element known as the channel base, and nylon brush fill that can be varied by trim length, density, and flexibility.

A brush strip filled with nylon filament is often used as a flexible brush seal on equipment. A strip seal brush functions as a flexible shield against mist, dust, light, heat, or intrusion into a point of operation. Nylon strip brushes can function on conveyor lines as a product hold-down,as an applicator of wet or dry coatings, or as a passive duster or wiper to sweep away loose debris or to redirect or stabilize your moving product. Using conductive nylon, available in a 20% mix with regular nylon or in a 100% conductive format, you can also create a static reduction strip brush.

Nylon 6-12 is approved for use in direct food-contact applications. Stainless steel strip brush components are also ideal in environments where the brush wire may be exposed to moisture or high humidity on a repeated basis. We feature 304 stainless steel channel and holding wire.

Inserted into a paddle wheel style cylinder assembly for conveyor cleaning applications, replaceable nylon brush strips can allow you to economically perform brush refills in-house.

Nylon 6.6 is a medium grade of filament suitable for most dry industrial applications. Spiral Brushes Inc. uses nylon 6.6 as our regular duty filament for most industrial applications. Compared to nylon 6.12, nylon 6.6 has a higher moisture absorption rate at 9%. It therefore loses approximately half its stiffness when exposed to wet environments. Nylon 6.6 also has limited resistance to many common chemicals.

Nylon 6.12 is a higher performance grade for industrial and food-contact applications with the following attributes: a significantly greater wet stiffness modulus than 6.6 nylon, resistance to petroleum distillates, benzene aromatic hydrocarbons, ethyl acetate esters, and trichloroethylene hydrocarbons. Nylon 6.12 is FDA approved for direct food contact.

Heat stabilized nylon has been post-extrusion treated to raise the temperature where the loss of physical properties becomes evident.

Conductive nylon is available for static reduction applications in both a 100% load and a lower 20% load for cost reduction. Conductive nylon can be mixed with other brush fill materials to provide static reduction along with other brushing functionality at a more economical cost.

Abrasive nylon is a hard working filament choice not often used for strip brush manufacturing but can be used extensively in powered brushes for deburring, surface finishing, edge blending, or radiusing after machining. Power brush formats include: wheel brush , cup brush , end brush and powered cylindrical brush applications.

| Material Properties | 6-6 Nylon | 6-12 Nylon | Polyester | Polypropylene |

|---|---|---|---|---|

| Stiffness Modulus Dry |

512

|

450

|

450

|

745

|

| Stiffness Modulus Wet |

160

|

400

|

447

|

700

|

| Water Absorption % |

9%

|

3%

|

0.33%

|

0.03%

|

| Bend Recovery % |

90%

|

90%

|

90%

|

75%

|

| Softening Point (°F) |

250°

|

250°

|

250°

|

240°

|

| Melting Point (°F) |

495°

|

410°

|

482°

|

330°

|

Nylon is available in both black and natural (milky clear), and on special order in a variety of colors to meet customer requirements. Both crimped and level material formats are available. Crimped nylon brush fill is preferred in power brush applications to extend fatigue life, while level (non-crimped) may be preferred for brush seal applications to increase brush density. A range of filament diameters are available from 0.003″ (very fine) to 0.060″ (stiff) to suit specific applications and a variety of trim length requirements.

Nylon is available in both black and natural (milky clear), and on special order in a variety of colors to meet customer requirements. Both crimped and level material formats are available. Crimped nylon brush fill is preferred in power brush applications to extend fatigue life, while level (non-crimped) may be preferred for brush seal applications to increase brush density. A range of filament diameters are available from 0.003″ (very fine) to 0.060″ (stiff) to suit specific applications and a variety of trim length requirements.

We can mix nylon with other materials in a strip brush such as fine bronze wire (shown in above image) to accomplish desired functions,. We can also insert materials, such as thin metal foil, Teflon® fabric, or EPDM rubber sheeting, into the center of a strip brush to provide a solid barrier in addition to the brushing action. We will work with you to design and provide the exact brush required for your application challenge.

Nylon Strip Brush Holders

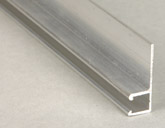

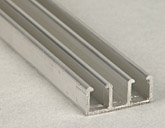

Spiral Brush also offers a variety of strip brush holders in sizes to fit whatever size strip you select:

Strip Brush Holder Vertical |

Strip Brush Holder Horizontal |

Double Channel Strip Brush Holder |

Stainless Steel Strip Brush Holder |

Stainless Steel Channel Clip and Steel Channel Clip |

Learn More About Nylon Strip Brushes

Have questions about replacing worn nylon strip brushes or have a new need? Interested in receiving a quote, or need help specifying a nylon brush seal? Contact Spiral Brushes to learn which nylon strip brush options are best suited for your specific application.

References:

Dupont Technical Information: Filament Performance in Brushes.

Polymers Inc, Buyers Guide to Synthetic Fibers. November 1987.